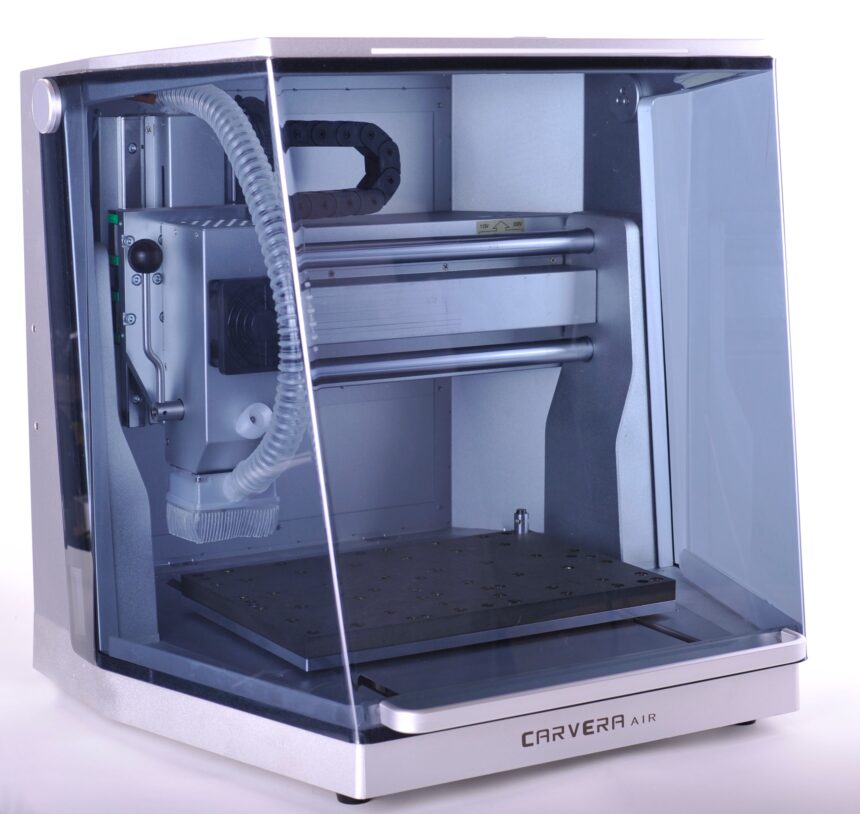

The Carvera Air may not be the biggest or most powerful CNC, but once you have one of these machines on your desktop, you might find it to be one of your go-to tools. This fully enclosed miniature CNC is only slightly larger than your average desktop 3D printer, but it can mill numerous materials including wood, plastic, and even metal. An optional laser module further expands the possibilities of this machine.

The original Carvera made a splash by introducing automatic tool changers (ATC) to the world of small benchtop CNC machines. Air has simplified things a bit to lower the price and make the machine more accessible. Most notable is the removal of the ATC function and replacement with a manual quick-change he lever. Sure, having ATC means it can do jobs that require multiple tools on its own, but the Air’s quick manual tool changes make multi-tool jobs easier.

Desktop CNC machines often feel underpowered and not stiff enough for serious work. Carvera Air’s die-cast metal frame and his 20mm linear rods make for a strong, stiff machine. 200 watt spindle cuts aluminum with ease. If there’s one place he criticizes the build quality of this machine, it’s on the front lid. It’s a little flimsy and bends when opened. At least on my unit, it meant that some of the internal seal that keeps dust out could peel off the lid.

Makera makes it easy to get started with Carvera Air by including multiple “getting started” projects that help you with every aspect of the machine, as well as using a variety of materials. I hate it when manufacturers ship machines without sample materials or an initial project to help new users get started quickly. It’s like buying a great new toy on Christmas Day only to find out you don’t have the right batteries for it. I especially like the included LED light project that guides you through the creation of his first PCB on the Air.

There are many options for controlling Air. We offer software for Windows, Mac, and Android. The front of the Android also includes a bracket for attaching the tablet to the machine (I hope to implement this option soon). I think the software could be a little more user-friendly, and while some operations aren’t completely clear at first, I think they’ll quickly become understandable once users run the included sample projects.

As far as CAM software goes, Carvera Air uses a GRBL-based controller, so a number of packages will work with it. Makera is currently working on its own CAM solution in beta. I currently have a Fusion 360 and VCarve configuration. New features in VCarve 12 (review coming soon) make Carvera Air and VCarve a winning pair.

While many other desktop CNC machines are fully enclosed to handle dust, the Air also has built-in dust removal (with the exception of vacuum). My unit is an early pre-production unit, and most of the dust collection parts are 3D printed, and to be honest, I wish it would stay that way. With any luck, Makera will release his STL file for the dust collection system, allowing users to print replacement parts or make their own modifications.

There are so many accessories for the Air that I’m way past the point where I want to continue reading this review, but I’ll also summarize some of the other accessories. Air includes a built-in probe for measuring materials (also includes a red dot laser for previewing job coverage), a fourth axis for near-3D rotary jobs, and engraves laser-capable materials Also includes an optional 5W laser module for .

As of this writing, there are only a few days left to participate. Kickstarter for this machine. If you’re looking for a desktop CNC, I can without hesitation recommend Carvera Air.