Ramaco Resources, Inc. (NASDAQ:METC) Q1 2024 Earnings Conference Call May 9, 2024 9:00 AM ET

Company Participants

Jeremy Sussman – EVP & Chief Financial Officer

Randall Atkins – Founder, Chairman, Chief Executive Officer

Christopher Blanchard – EVP & Chief Operating Officer

David Dyer – VP of Marketing and Analysis

Conference Call Participants

Lucas Pipes – B. Riley

Nathan Martin – The Benchmark Company

Operator

Good morning, and welcome to the Ramaco Resources First Quarter 2024 Results Conference Call. All participants will be in listen-only mode. (Operator Instructions). Please note this event is being recorded.

I would now like to turn the conference over to Jeremy Sussman, Chief Financial Officer. Please go ahead.

Jeremy Sussman

Thank you, operator. On behalf of Ramaco Resources, I’d like to welcome all of you to our first quarter 2024 earnings conference call. With me this morning is Randy Atkins, our Chairman and CEO; Chris Blanchard, our Chief Operating Officer and also in the room is our new VP of Marketing and Analysis, David Dyer.

Before we start, I’d like to share our normal cautionary statement. Certain items discussed on today’s call constitute forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. These forward-looking statements represent Ramaco’s expectations concerning future events. They’re subject to risks, uncertainties, and other factors, many of which are outside of our control, which could cause actual results to differ materially from the results discussed in these forward-looking statements.

Any forward-looking statement speaks only as of the date on which it is made except as required by law, Ramaco does not undertake any obligation to update or revise any forward-looking statements whether as a result of new information, future events or otherwise. I’d also like to remind you that you can find a reconciliation of the non-GAAP financial measures that we plan to discuss today in our press release, which can be viewed on our website, www.ramacoresources.com.

Lastly, I’d of course encourage everyone on this call to go on to our website and download today’s investor presentation.

With that said, let me introduce our Chairman and CEO, Randy Atkins.

Randall Atkins

Thanks, Jeremy. Good morning to everyone and thanks for joining the call. Our first quarter results were of course below our expectations. We printed $24 million of EBITDA in Q1 against twice that amount in Q4. Jeremy will go into detail on the financial metrics, but a main driver was lower realized prices. They dropped by over $55 a ton or almost 20%, since Q4. This particularly hit us in March when we shipped almost 50% of our Q1 export business which was export, which was index priced.

We also dealt last quarter with mine cost issues at Elk Creek from both tough geology and labor conditions. I’m confident that our results will improve throughout the year. This will come from a combination of continued production growth, greater cost discipline and improvements in productivity. With that expectation in mind, we have continued to maintain our current guidance for the year.

As I said in our earnings release, there are parallels with our somewhat bifurcated performance in ’23. Last year, we were both a different and much larger company in the second half of the year. Why? Essentially, we grew by 33% from 3 million to 4 million tons of annualized production in the back half. 2024 looks like it may play out in very similar fashion. We now expect to ramp current sales and production by an additional 1 million tons or 30% by Q4, and in the year at basically a 5 million ton run rate. We will reduce CapEx in ’24 by 30% against ’23 numbers. In the balance of the year, we will also see a meaningful cost reduction back to guidance levels from a combination of new production and better mining conditions as I will briefly note in a moment.

Later, we’re also going to talk in detail about each of our four near term production growth initiative. All of them are currently on track on both timing and budget. In a brief summary, at Elk Creek, we will add roughly 600,000 tons of additional annualized production from the Ram 3 surface and highwall mine as well as a new third section to the Stonewall (sic) Stonecoal Alma mine. Both ramp up by the mid-year and these mines will be in thicker coal cost with cost rather estimated at approximately $90 to $95 a ton.

In the main Berwind mine starting in Q4, we will add roughly another 300,000 tons of annualized low vol production from adding a third section. That mine is now running with cost of approximately $85 per ton and we’re expecting similar cost metrics in the new section. Lastly, we are on track to have the Maben prep plant fully operational before year end. This will eliminate about $40 per ton of current trucking cost. So collectively in the back half we should be producing and selling on an annual basis of almost 1 million tons more.

Importantly, this new production should have average mine cost well below $100 per ton. And this is combined with productivity gains at our other mines, we anticipate overall cost will decline meaningfully in the second half. Our bottom line goal is to exit ’24 at or below $100 per ton cash cost and produce and sell at almost a 5 million ton annual rate. This is now baked into our full-year cash cost guidance of $105 to $111 per ton.

On our Rare Earth Element business, since we last spoke last quarter, we have moved forward on a number of fronts. In March, Weir International issued an updated technical report on our exploration target. Both the rare earth volumes and mineral concentration estimates basically doubled from the original report a year ago. We are currently drilling more cores at deeper depths and also mining larger test samples. As we do, we anticipate these numbers will get larger.

There are two matters on the rare earths I’d like to note. There are a number of deposit lithologies that showed maximum part per million concentrations exceeding 9,000 ppm this includes coal. Also 10% of the deposit is now estimated to contain two high value critical minerals called gallium and germanium. These are used in semiconductors and both were banned from export by China last year. We are now estimated to have one of the largest natural supplies of these minerals in the U.S.

On the back of the New Weir report in April, we held our first inaugural investor REE conference call with both the buy and the sell side. We would like to thank nearly all of the 200 people who participated who were both a lot of new and many familiar faces. We are continuing to progress at the Brook Mine in terms of developing the geological assessment as well as the chemical and preliminary separation analysis of the REs. And we still expect completion of our techno economic analysis later this year.

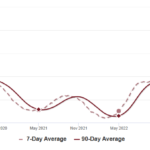

Switching gears, in terms of the overall met market, Jeremy will touch on some detail in his remarks. However, met coal prices as I said fell by roughly $55 throughout the first quarter. In March alone, the drop accelerated by $30 a ton. As I mentioned, unfortunately March was when we had the majority of our first quarter export shipments. This price decline was largely on the back of muted seasonal buying influences, which we’ve now seen occur in Q1 for the last three years in a row. Some good news however is that pricing appears to have stabilized once again at levels similar to last year’s lows.

On the demand front, we have recently seen increased buying activity from several of our Asian customers. On the supply side, overall coal production is down in cap year-to-date with Southern West Virginia down about 14% and Virginia down about 21%. This decline is reflected with the recent closure of some higher cost mines near us that are frankly losing money at current price levels. One silver lining of these closures is that the labor markets seem to have stabilized. As a result, our hiring has picked up and wage pressures seem to have declined.

Although the met markets are always driven by macroeconomic factors, we’re optimistic that the back half of the year may show some resiliency in both demand and pricing. There are a number of factors, which we expect may lead to this rebound. In a nutshell, Chinese domestic steel demand has been weak this year, which caused them to increase their steel exports and that supply glut has led to lower steel prices across the region, which in turn has squeezed margins across the whole supply chain. As we know, China has been in a shift towards building out energy transition and consumer related industries at the expense of less spending on traditional real estate and infrastructure.

Looking forward, however, there are reasons to expect that the Asian steel markets may rebound in the second half of the year with a corresponding uptick in overall met coal pricing. First, in China, there’s a growing expectation of improving downstream demand due to recent project funding via accelerated bond issuances. In addition, India has progressively had a larger role in impacting the global met business.

This may be equal or even greater than Chinese market influence as we move forward. And one aspect of this influence on the markets we’ve seen is that now both India and China’s seasonal buying patterns have more weight on price. As an example, China seems to be a more aggressive buyer in Q4 for their Q1 construction activity and India seems to restock ahead of the monsoon season in Q3. Also this year Indian elections are taking place this quarter which has added to softer infrastructure spending. To note, there is a prohibition of approving new infrastructure projects during the election season.

So this adds another impact. Therefore, we view India’s recent demand pullback as somewhat of a seasonal one and post-election we expect an uplift beginning in July. So to step back against this backdrop of international demand, we couple it with a forward muted supply picture from the closure of some higher cost mines in the U.S. and continued production issues at some of the older Australian mines. This leads us to feel some optimism that we may see both demand and price pick up in the second half.

Indeed as I’ve said over the last few weeks, we have seen some increased sales interest from our Asian customers. And we should also not discount the knock on demand impact if the U.S. economy shows some strength in the back half of the year. We expect this might come from the combined impact of spending rollouts from the multiple fiscal stimulus packages passed last year and the resulting on shoring or reshoring of related energy transition projects.

Lastly, on our financial front, we recently closed an agreement to increase both the size and the term of our existing revolver with a key bank led syndicate. This facility takes the basic size of the revolver from $125 million to $200 million. It has an additional $75 million accordion feature which increases the ultimate size to $275 million. We also extended the term from three to five years until 2029.

As we look to our production and sales growth over the coming years, we appreciate now having the flexibility of a larger facility to basically meet normal working capital requirements. And I want to thank especially KeyBanc as well as our syndicate members for their long and continued support of Ramaco and all our growth initiatives.

I view the closing of this upsized facility as a validation of our longstanding strong credit culture and conservative balance sheet. In line with that, I would note that over the course of ’24, we will continue to pay down the term debt we had at the end of the year as Jeremy will detail in a moment.

And with that, I would like to turn the floor over to the rest of our team to discuss finances, operations and markets. So Jeremy, please begin with a rundown on our financial metrics.

Jeremy Sussman

Thank you, Randy. As you noted, first quarter 2024 results were negatively impacted by lower index pricing especially in March. We shipped over half of our export tons in March and indices were at their lows. In addition, Q1 mine costs were impacted by challenging geology and labor constraints at Elk Creek both of which are expected to improve throughout Q2 and especially in the back half of the year. Now to get into some specifics, Q1 adjusted EBITDA was $24 million compared to $48 million in the same period of last year.

Primary reason for the year-over-year decrease was the 20% decline in index pricing, which led to a similar decline in our realized pricing to $155 per ton versus $188 in Q1 of ’23. Overall net income was $2 million compared to $25 million in Q1 of ’23. While net income was positive, Class A EPS was 0. Now as a reminder, when calculating Class A earnings per share, net income is reduced by the Class B dividend declared in that quarter.

At the same time, our cash cost rose from $109 per ton this time last year to $118 per ton this past quarter. Sales of 929,000 tons were up 23% year-over-year on the back of both higher production and sales from inventory. That said, while production of 844,000 tons was up 10,000 tons from Q1 of ’23, this missed our internal expectations on the back of both challenging geology and labor constraints at Elk Creek, which led to higher costs.

Increased purchase coal especially on the low vol side also negatively impacted our cash cost by a couple of bucks a ton. Put some metrics behind the production miss, we believe the combination of challenging geology at our Elk Creek Complex’s Stonecoal Alma mine coupled with labor constraints cost us over 100,000 tons of production in Q1. Biggest labor challenge was staffing up our Michael Powellton mine, which produced just 20,000 tons of coal this quarter, almost 50,000 tons below what a normal quarter would look like.

Good news is that based on a loosening labor market due to mine closures around us, this mine is now essentially fully staffed as of early May. On the geology front, Chris will talk through this in more detail, but our Stonecoal Alma mine had to mine through some very thin coal in Q1. This mine came in almost 30,000 tons below what we had expected for the quarter. Good news is that after continued challenging conditions in April, the second section is now pillaring for the rest of the year and thus is in much better conditions.

This should lead to much higher production and lower costs. Had we produced at overall expected levels in Q1, we are confident that cash costs would have come in the full-year guidance range of $105 to $111 per ton. Looking ahead, we anticipate Q2 shipments of 850,000 to 950,000 tons of coal and expect an increase in sales guidance throughout the year. As Randy noted, over the balance of the year, Ramaco anticipates adding almost 1 million tons of annualized production compared to current run rates all from projects that are fully underway.

Overall mine costs are expected to meaningfully decline in the back half of this year as volumes are anticipated to be materially above those levels in the first half of ’24. For the full-year, we are reiterating all prior 2024 guidance which you can of course find in our guidance tables.

I’ll note that at the midpoint of guidance, we anticipate both production sales up 30% versus 2023, a decline in cash costs and a 30% decline in CapEx. That said, based on the three new mines or sections that we’re adding throughout the year, we clearly anticipate results to be back half weighted.

Moving to the balance sheet. Our liquidity on March 31 of $96 million was up 46% year-on-year. This is despite the fact that accounts receivable hit record quarter end levels of $104 million in March, up over $30 million on the year. As Randy both said and provided specifics on, last week we closed on our $200 million revolver up from $125 million and extended the term into 2029. I want to thank our KeyBanc and syndicate partners for their support of Ramaco as well as our growth strategy.

Now on Page 8 of our slide deck, we have a chart that illustrates our commitment to maintaining a conservative balance sheet. Specifically, we have continued to meaningfully pay down term debt over the past few quarters including in Q1. One year ago, we had roughly $140 million of total debt outstanding. We reduced that figure by roughly $55 million to just $86 million which includes amounts drawn on the revolver as of the end of Q1. We will repay the final $9 million of term debt associated with the Maven acquisition over the next few months.

This essentially leaves us with just the $35 million unsecured baby bond, which we can choose to repay at any time, but is not due until 2026 plus whatever we have drawn on the revolver for working capital purposes. As of Q1, our net debt to trailing 12 months EBITDA was less than 0.4x.

Before I turn the call over to Chris, I’d like to add on to Randy’s remarks on the market. We’re now essentially sold out at the midpoint of ’24 production guidance. We have 1.4 million tons committed to North American customers at an average realized price of $167 per ton and 700,000 tons that have mostly already shipped to seaborne customers at an average realized price of $150 per ton for a total of 2.1 million tons committed at an average realized price of $162 per ton.

We also have an additional 2 million tons committed at mostly index linked pricing for delivery to export customers with over half of that index linked pricing on the low vol side. This brings total commitments to 4.2 million tons, up from 3.9 million tons when we last spoke. At this point, we’re essentially 100% sold out through year end with the ability of course to pivot to higher levels dependent on market conditions. In addition, in the wake of the Baltimore bridge collapse, I want to reiterate that Ramaco does not ship through the port of Baltimore. We’ve got dedicated throughput to export our coal through various Hampton Roads coal terminals in Virginia. Thus, we’ve seen zero direct impact to our business as a result of the bridge collapse.

Switching gears, in Randy’s remarks, he discussed the reasons behind the Q1 drop in pricing and the reasons for optimism in the second half of this year, which I’m going to elaborate on. First, we’re witnessing the effects that low prices are having on high cost Central App supply around us. Specifically, we are seeing the most amount of incoming job applications for our mines that we’ve seen, since last summer. Frankly as a number of higher cost competitors operations have either shutdown or scaled back.

Second, on the demand side, Chinese steel demand disappointed in Q1 on the back of continued struggles in the real estate sector in particular. In addition, while Indian steel production has remained up double-digits year-on-year in Q1, Indian’s met coal buying activity was not as robust as it was in the second half of ’23.

That said, looking forward, India’s most recent PMI data showed that its business activity expanded at the fastest pace in almost 14 years. When combined with an expectation of a further pickup in activity post both their elections and monsoon season, we’ve expect India to be very supportive of met coal markets in the back half of the year.

Now China is always a bit more difficult to handicap. It’s been a slow start to the year there on a number of fronts including loan growth. That said, as Randy mentioned, there’s a growing expectation that credit growth will accelerate in the back half of this year. If that’s the case, while we would expect both the U.S. low vol and high vol pricing to rebound, this should especially be true on the low vol side.

Frankly, low vol is essentially sold out across the Board for many producers and while current U.S. indices remain muted, we do not believe they necessarily reflect the current tightness in the U.S. low vol markets in particular. We’re seeing both domestic and international inquiries on the low vol side for 2024 delivery candidly at some pretty solid pricing.

That said, I’d now like to turn the call over to our Chief Operating Officer, Chris Blanchard.

Christopher Blanchard

Thank you, Jeremy, and thanks everyone for joining our call this morning. As Randy and Jeremy both alluded to, the first quarter was extremely challenging operationally on several fronts. First and foremost, exiting ’23, the labor market for experienced and skilled underground coal miners was extremely tight. While our turnover rates have moderated from unsustainable levels in the previous year, we were not as successful as typical in filling some vacancies at our operations. This shortage was the most acute amongst the scarcer skilled positions. And while all of our complexes saw this trend, the bulk of the impact was at our Elk Creek operations, which were in Logan County, West Virginia and in close proximity several of our peers.

However, the recent precipitous drop in the coal pricing indices has had one positive effect. Some of the higher cost operations in the region have been scaled back or outright idled. And as a result, we are seeing an overall loosening in the labor market with both more quality applications received as well as a reduction in our natural turnover.

To put some metrics to the effects of these vacancies on the operations, we entered the year at Elk Creek running with approximately a 15% vacancy rate from our targeted staffing levels. By the end of the first quarter, staffing vacancies are less than 10% at Elk Creek and our annualized voluntary turnover rate has decreased by approximately 4% overall as well. This is critical in particular at one of the main mines at Elk Creek, which was understaffed for its budgeted production levels for the first several months of the year. It is now almost fully staffed with production levels rising to meet our expectations.

At the corporate level, we’re taking a measured look at each mine and at each section within each mine given the coal markets and near term cost pressures. As geologic or other challenges occur, we are rightsizing underperforming mines to manage overall mine cash costs.

Switching to those geologic challenges, as mentioned, our stone coal mine at Elk Creek progressed through difficult mining conditions on both of its super sections during the quarter. Due to moving to predominantly retreat mining on one of these sections and transitioning another section into the thicker Alma seam, where coal heights will be approximately 50-inches or greater compared to 30-inches or less. We now expect to reverse the production misses at Stonecoal as well as see a substantial decline in cash costs for the remainder of this year heading into 2025.

At Elk Creek overall, we expect an uptick in the second half of the year in production levels. As some of the issues I’ve just described these. More importantly, we’ll see the new Ram 3 surface and highwall mine begin production in the second half being fully ramped up in an additional 350,000 ton per year rate by the end of the third quarter. Our staffing for underground mines remains a challenge. The labor pool for surface miners is much more amenable. This mine will start up essentially fully staffed as each spread is put into operation, meaning that the ramp up period will be very short. Excuse me — initial development work has revealed favorable mining conditions even compared to our Ram 1 surface mine.

On a more positive note, our Berwind complex in general and the Berwind mine specifically continue to perform well and exceed our projections each month. Bolstered by the favorable geology of the Pocahontas 4 seam, productivity remains above budget. The recent completion of our Triad 2 coal mine allowed us to shift labor to fill vacancies at Berwind and our other coal mines in this division, again bumping our productivity. We are on schedule and on budget with the expansion of the Berwind mine. There, the surface site preparation is well underway for the series of shafts and an elevator that will be excavated and installed starting this summer.

As we’ve previously discussed, completing the first of these shafts and increasing our ventilation capabilities is the gating item for the start of our third super section at Berwind. Expect this section to begin production in the third quarter of this year and to be fully ramped and operating at the levels of the initial two sections by year end ’24. At that point, the individual Berwind mine will be Ramaco’s largest and produce 900,000 to 1 million tons annually by itself.

Finally, work is progressing ahead of schedule at Maven on the construction of the new preparation plant. The modular plant we purchased in March has been completely taken down and transported from Alabama to site at Maven. Earthwork for the foundations for the preparation plant and the initial facilities are complete on-site and the actual plant footers will begin construction next week. We continue to expect that the preparation plant will be operational during the fourth quarter of 2024. This will immediately result in a $40 per clean ton reduction in our raw coal trucking costs from Maven. We’ll also affords the option to potentially expand the production portfolio at Maven into the other quality low volatile seams we control on the property and give us additional purchase coal opportunities.

Summing up, we’re glad to be out of the first quarter knowing we have some of the headwinds behind us. We expect the second quarter to complete setting the table for the balance of 2024 with a step change upwards in production as Ram 3 and Berwind 3 begin operation. This keeps us on our trajectory to exit the year at over 5 million tons per annum production sales — and sales with significant reduction in our operating cash cost as well.

This now concludes management’s prepared remarks. At this time, I’d like to turn the call back over to the operator. Thank you.

Question-and-Answer Session

Operator

We will now begin the question-and-answer session. (Operator Instructions). Our first question will come from Lucas Pipes with B. Riley. You may now go ahead.

Lucas Pipes

Thank you very much, operator. Good morning, everyone. Randy and team, my first question is on your growth this year, and I wondered are you kind of fully locked and loaded on this equipment we’re hearing from some of your peers is still hard to come by. Is all of that equipment procured and on-site are you waiting for that to come in? And then on the labor side it sounds like there is some easing, but do you have to keep staff already hired and ready to go? And then anything on the market side that could change plans at this stage, could you hear the market is stabilizing, but wondering how you think about that? Thank you very much.

Randall Atkins

Okay. So Lucas, I’ll take a stab at a couple of your questions, and then I’m going to turn it over to Chris to give you maybe a little more granular detail on equipment and labor. So just in somewhat order, equipment wise, interestingly you asked that we have just recently purchased a good deal of new underground equipment really within the last few weeks. So I’ll let Chris detail that, but we’re ahead of the curve on that game.

On labor, again, I’ll let Chris detail, but we’ve had a very tight market as many of our peers have noted as well. That’s loosening we’ve had particularly the Elk one mine and especially that was frankly understaffed and that understaffing led to obviously lower productivity as well as production numbers. We’re getting those spots filled. And as I said that hopefully will result in a turnaround moving forward.

And in terms of our sort of overall market plans, we have baked this production in, because we’ve essentially sold all the tons. And so it’s not as if we were hanging out there with a great deal of unsold production moving into the balance of ’24. We have retained some optionality probably through maybe one or two tweaks and maybe some purchase goal to take our guidance numbers up to the higher end or maybe even to touch above that as we progress in the year. But obviously we’re not going to do that, unless we see the market behaving in a manner in which we would be encouraged to move in that direction.

So Chris, why don’t you fill in a little bit more detail on equipment and labor?

Christopher Blanchard

All right. So Lucas, as Randy noted and you did, equipment — mobile equipment particularly for underground is extremely scarce and we were fortunate enough to fulfill all of our ’24 needs on underground equipment and rebuilds really and sort of lock that in the last month. Moving forward, also within the last, I think two weeks, we’ve locked in our slots for ’25 and ’26, so that we can have a secure position going forward. But we don’t have any material CapEx left to spend for any of the expansion mines that we’ve talked about.

And of course, fortunately, we’re pushing them as fast as we can, but they are going to be our lower cost profile than what we’re currently running. So we’ll have some optionality there based on what the market dictates. I’m sorry, Lucas.

Lucas Pipes

No, no. Sorry, go ahead.

Christopher Blanchard

I was just — I skipped your labor question. I was going to mention that we have seen the labor market. I wouldn’t say it’s softened exactly, but it’s moved back to a more healthy position as far as miners moving around and the way the availability of skilled miners and liker our peers, I’m sure we have ramped up our training efforts for new electricians, new miners as well internally.

Lucas Pipes

Thank you. Chris, one quick follow-up on the equipment side. Is it new or rebuilt equipment? And when would you expect it to be delivered if it’s been procured recently? Thank you.

Christopher Blanchard

So rebuilt equipment and that in the out years also that’s just for rebuilt slots. We’ve taken delivery of two of the six pieces that we acquired and expect to take delivery of the remaining four within the next, call it six weeks.

Lucas Pipes

Great. Thank you very much for that. For my second question, Jeremy, you know how it works, right? The release comes out, you update your contract book, we compare that to the prior hedge position and I backed into $146 per short ton on your export tons incrementally sold during the quarter. And first, does that seem about right versus where you’ve been selling tons? And today, how would your average export sales compare to that figure? Better, about that same level, worse, would appreciate your thoughts on that? Thank you.

Jeremy Sussman

Sure. Good question, Luca. So, yes, I agree with the math. Obviously, when you look at our Q4 release versus the incremental call it 500,000 tons or so that’s been priced since then. I think as Randy kind of noted in his comments, half of our — over half of our export tons just by sort of luck of the draw were shipped in March when indices were at their lows. So I mean when you look at it on a go forward basis, I would say our Q1 realizations were lower than you would expect on a quarterly basis. Now the bad news of course is since Q1 spot high vol is down another call it 13% or so. So I mean we’re not in the prediction game in terms of predicting where the spot market goes. But obviously if prices hold, you’ve got to take the indices into account when looking at our realizations for Q2.

Lucas Pipes

Thank you very much for that Jeremy. I’ll try to squeeze one last one in. First, on the retreat mining, when and for how long does that occur? Obviously, that is very efficient, so trying to get a sense for what the potential benefits there. And with the idlings you’ve seen across the industry, any way to quantify the potential impact on 1,000s or 1 millions of ton basis? Thank you.

Jeremy Sussman

Lucas, I’ll jump on the retreat mining and then I hand it off on the impact on the idlings. But as you know, on room and pillar, usually you advance for a few months and then you retreat for a few months. At our Stonecoal mine in particular that we mentioned, just the way that that mine was laid out, we basically advanced for about three years and we will be retreat mining there for the remainder of ’24 and actually into ’25 on one of the sections and the second section will be retreat mining for about half of the year.

So it will be an abnormally high amount of retreat mining after an abnormally amount of the more expensive advanced mining. So I hope that answers your question. The rest of the mines at Elk Creek are more or less on that same schedule.

Randall Atkins

And Lucas to your second part of your question about the idling, I mean, I gave you some macro numbers for the quarter for sort of Southern Central App, West Virginia production was down about 14%, Virginia production was down about 21%. So that gives you some general notion of sort of directionally where the production figure during the shake out and obviously in Virginia as an example where we’ve got a number of operations, a 20% plus decline is a fairly meaningful one.

Lucas Pipes

I appreciate all the color. Thank you very much and to you and the team best of luck.

Randall Atkins

Thank you.

Operator

(Operator Instructions). Our next question will come from Nathan Martin with Seaport Global. You may now go ahead.

Nathan Martin

It’s actually with The Benchmark Company. But thank you, operator, and good morning, guys. I want to start out on the pricing front as well. As mentioned, production essentially fully committed at this point. But given the volatile spreads we’ve seen so far this year between the Australian indices and U.S. Indices, any way we could kind of get a breakdown of how you guys expect your remaining seaborne contractor position to kind of be split between those Aussie and U.S. Embassy?

Jeremy Sussman

Yes, Nate. So I’ll give you some color on that. So first of all in terms of our overall cadence about a third of our coal will go domestic this year and then two-thirds will go export. I’d say within the export side, Europe and Asia are pretty equal. Let’s call both about 30% of our business and then the remaining call it 10% or so goes into South America. Europe and South America is all going to be against the U.S. indices both low vol and high vol.

A lot of the Asian business is actually not all of it but a fair amount of it is priced off of either the PLV or some other Aussie index which of course is more linked to the low vol than the high vol side. So when all is said and done, we’ve got about 2 million tons or so of index linked business left to ship. Over half of it is either directly low vol or linked to an Aussie PLV or similar type index.

Nathan Martin

Hi Jeremy, appreciate that, that’s very helpful. Maybe just along the same lines, given current market conditions, what kind of capture rates are you guys getting versus some of those U.S. Indices, high vol A, high vol B, and are you seeing any discounts in the marketplace?

Jeremy Sussman

I mean, as we said in our remarks, the U.S. low vol market itself is quite tight. So any discounts there are if there are they’re pretty small. I’d say that the high vol markets are certainly a bit more oversupplied than low vol. But as Randy noted, I mean that’s really where you’re seeing a lot of the higher cost operations shut down. So certainly from our standpoint, we’re certainly optimistic about kind of the cadence throughout the year between the combination of kind of supply shutdowns and also the fact that we don’t think that the U.S. low vol indices frankly reflect the current tightness.

Randall Atkins

And Nate one other point which again is maybe a somewhat obvious one, but I think in terms of the decline in production that we’re seeing in the Central App area, there’s probably going to be call it a quarter lag in terms of how that starts to impact pricing and availability on particularly the high vol markets. But I do think it’s coming. So I would look toward the back half of the year is firming up frankly for a number of the reasons we cited on a macro basis. But on the supply side in Central App, I think that’s when you’re going to start to see a little bit of impact particularly as it relates to of course export shipments.

Jeremy Sussman

And Nate on the low vol side, I’d even say — I’d even mention that there have been some even domestic inquiries lately. So again we think that markets, we feel good about that market today. And as Randy said, certainly feel good about the high vol market in the future.

Randall Atkins

Yes. I will give you an anecdote Nate when you see one trading group ask for a bid, you feel hopeful. When you see two, ask for a bid at the same time, you feel a little suspicious. When you see four asking for a bid at the same time, you begin to think that somebody knows something perhaps you don’t. So I take some comfort in the directional side of what we’re seeing out there in the market right now.

Nathan Martin

Got it. Got it. Appreciate that anecdote, Randy. Maybe just thinking about logistics for a second guys, I know Ramaco wasn’t directly impacted by the unfortunate Baltimore port outage, but any comments on how that’s maybe indirectly impacted your rail service to Hampton Roads, for instance?

Randall Atkins

Yes. Chris, you want to take that one?

Christopher Blanchard

I mean, honestly, Nate, we didn’t see too much impact. I think some more coal was moving to the other peers, but as far as service from frankly both of our railroads, they’ve been pretty much just in time and getting the inventory to our customers as we produce it and as it’s ready for shipment.

Nathan Martin

Okay. Great to hear, Chris. Maybe shifting over the cost side real quick, obviously you guys mentioned new mines coming online this year should improve the mix with lower cost expected with $90 to $95 a ton, maybe in prep plants coming online hopefully before year end which will reduce trucking cost. So kind of putting all that together I think you said hoping to hit an exit rate of around 100 or maybe even less. So any early thoughts on how these items could kind of translate into what to expect for cost in ’25, like how much did those improve versus this year’s guidance of what is it 105 to 111?

Randall Atkins

Yes. I mean Nate. So I think obviously we’re a long time away from our ’25 budget. And if we just take sort of the call 5 million ton exit rate don’t layer in any tons or anything like that. Honestly the exit rate is a good way to look at next year. I mean obviously I think Q1 will certainly be our highest cost quarter. Q2 is still going to be above the high end of the range really more just due to the fact that some of the labor and geology issues persisted into April. But those are behind us.

And so as Chris noted once we layer in all this kind of call it $85 to $95 a ton cost mines throughout the course of the year that’s what really gets you to a step change in the back half of the year and certainly exiting the year when all of that’s online.

Christopher Blanchard

Yes and Nate, as we’ve said several times before, obviously, we’re on a growth trajectory to get probably to 7 million to 7.5 million tons over the next few years. Obviously, we can calibrate that depending upon and will calibrate it depending upon market conditions. So to look forward into ’25, we will still be in growth mode assuming that the market is there. And as we grow more tons just by virtue of the math, if nothing else, it’s going to help us on cost.

Nathan Martin

Okay, got it. Very helpful guys. I’ll leave it there. Appreciate the time and best of luck in the second quarter.

Christopher Blanchard

Thanks, Nate.

Operator

This concludes our question-and-answer session. I would like to turn the conference back over to Randall Atkins for any closing remarks.

Randall Atkins

Again, as always, we thank everybody for joining us today and we look forward to catching up with you after the end of the next quarter. Take care.

Operator

The conference has now concluded. Thank you for attending today’s presentation. You may now disconnect.