Mastercam Deburr is transforming the machining industry. This innovative tool delivers unparalleled precision, high quality and increased efficiency, helping to set a new standard in deburring. Say goodbye to time-consuming manual finishing processes and frustrating problems caused by burrs. Mastercam Deburr paves the way to smoother, more efficient work.

This powerful tool integrates seamlessly into your Mastercam setup to streamline deburring, ensure superior control, and eliminate the need for manual intervention. For machinists and manufacturers focused on improving quality and efficiency, Mastercam Deburr is an essential addition.

What is Mastercam deburring?

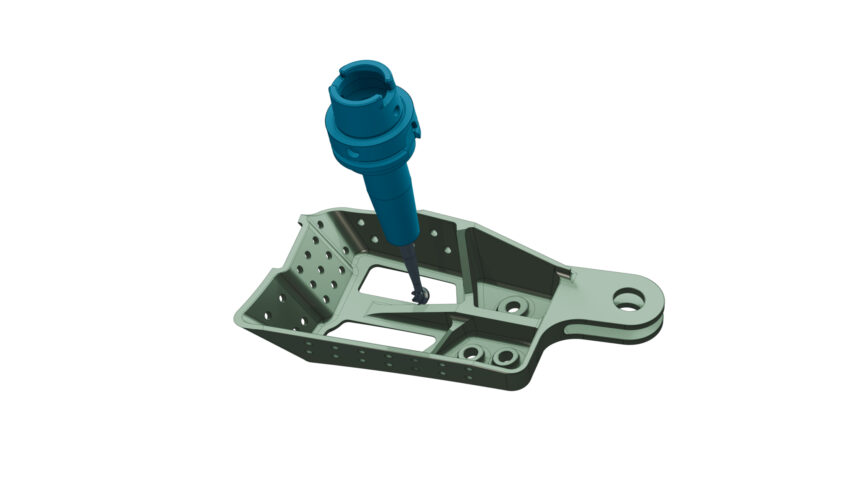

Mastercam Deburr is a comprehensive solution for removing burrs, small, often sharp defects on the edges of machined parts. Burrs can be a problem. These complicate the machining process, affect workpiece alignment, reduce finish quality, and may require additional steps to meet quality standards. With Mastercam Deburr, you can automate this process, improve the quality of your finished parts, and focus on other key tasks.

Integrating Mastercam Deburr into your workflow gives you a tool that not only removes burrs, but transforms the way you manage your machining finishes. Mastercam Deburr takes a precision-based approach to tackling and solving these challenges, helping you produce high-quality end products.

Key features of Mastercam Debari

Mastercam Deburr brings together a set of advanced features designed to make deburring faster, easier, and more accurate.

- automatic edge detection: This feature automatically identifies and highlights areas with burrs, simplifying the deburring process. Defects can be easily found and removed without the need for manual inspection.

- User friendly controls: Mastercam Deburr has an intuitive interface that minimizes the learning curve and maximizes productivity. The controls are easy to access and operate, so even new users can master deburring quickly.

- Wide range of tool compatibility: Mastercam Deburr supports a variety of tools, including ball mills, lollipop mills, and full-radius taper mills. This flexibility makes it suitable for a variety of deburring strategies, both in 3-axis and 3+2-axis configurations.

- Improved productivity: Deburring directly on the machine not only saves time but also improves overall workflow efficiency. Mastercam Deburr eliminates the need for hand finishing, allowing machinists to complete jobs faster while maintaining high quality standards.

- Seamless integration and ease of use: Mastercam Deburr easily integrates as an add-on with existing Mastercam licenses, including 2D and 3D Milling, Mastercam Router, and Mastercam Mill-Turn. Users can access it from the 3D toolpath gallery for finishing types or directly from the toolpath manager.

Why choose Mastercam deburring?

Deburring is essential to ensure machined parts meet quality and safety standards. Removing burrs reduces potential risks during assembly, improves the aesthetic quality of parts, and ensures smoother installation in precision-critical applications. Mastercam Deburr doesn’t just provide a solution. It provides a streamlined way to manage deburring, complementing and enhancing your machining workflow.

How Mastercam Deburring Can Improve Your Business

Mastercam Deburr is more than just a tool, it’s a strategy to reduce costs, minimize processing time, and increase factory productivity. This tool allows your shop to produce cleaner, more accurate parts in less time, so you can work more and be more profitable. Additionally, manual finishing steps are reduced, ensuring a smoother, more consistent finish across multiple parts.

Mastercam Deburr helps you stay competitive in today’s fast-paced manufacturing environments by increasing productivity and efficiency. Ideal for manufacturers looking to optimize their processes without compromising quality.

Are you ready to improve the efficiency of your shop?

Mastercam Deburr allows you to improve the quality of finished parts and increase overall productivity. This innovative tool is designed to streamline deburring, reduce costs and eliminate the need for hand finishing, saving time while delivering unparalleled quality.

If you’re ready to improve your deburring process and experience the benefits of Mastercam Deburr in your shop, learn more about how Mastercam Deburr can transform your operations. Mastercam India will also be exhibiting. IMTEX 2025one of India’s leading manufacturing technology trade fairs. The company address is: Hall 1B, Booth A-102 At an event from January 23rdrd Until January 29thth, 2025. Mastercam India is a provider of computer-aided manufacturing (CAM) software for CNC machine programming, offering a wide range of solutions for various industries. Visitors to the Mastercam India booth can learn more about the company’s products and services as well as speak with experts about their specific needs. For more information, please visit the Mastercam India website. https://mastercamindia.com/

About Mastercam India:

Founded in 2016, Mastercam India Pvt. Ltd. is headquartered in Pune, Maharashtra. The company offers Mastercam, a CAD/CAM software suite created to reduce production time and costs through efficient machining strategies and advanced toolpath technologies such as Accelerated Finishing™ and Dynamic Motion™ . Mastercam is the world’s #1 CAM software with over 300,000 installations in industries including aerospace, automotive, medical, tool manufacturing, energy, oil and gas, education, and prototyping. This product is sold through international channels of Mastercam India authorized resellers in South Asia and Middle East countries, providing local sales, training and support for 2-5 axis routing, milling, turning, 2-axis and 4-axis wire. We provide. EDM, 2D and 3D design, surface and solid modeling, artistic relief cutting, and Swiss machining. For more information, please visit:www.mastercamindia.com.