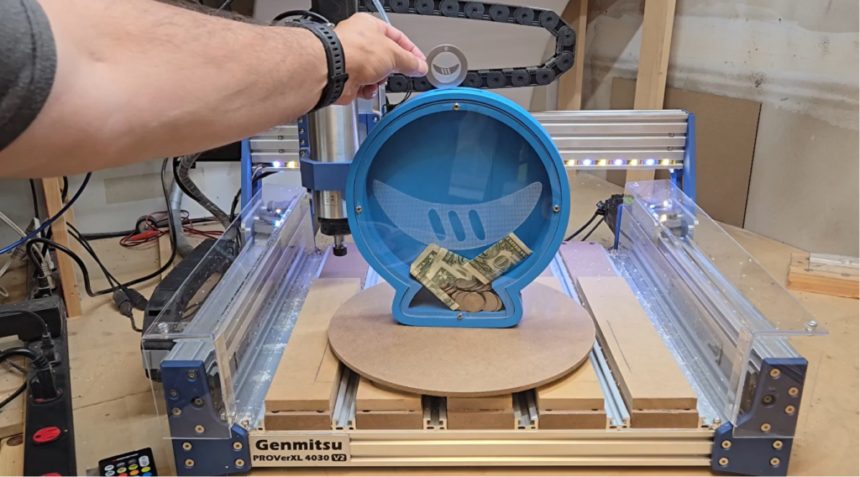

To celebrate SignSmart’s anniversary, Windsor Woodcraft, an avid SignSmart customer, embarked on a creative project to design and build a wooden and acrylic piggy bank. Genko PROVer XL 4030 V2 CNC Machine and Genko L8 20W Laser Engraving MachineWindsor Woodcraft has not only demonstrated the versatility of these tools, but also their own craftsmanship. In this article, we will discuss the processes, materials, and techniques used to bring this unique project to life.

To make this piggy bank, he used the following materials:

- 3/4 inch birch plywood: Selected for their sturdiness and ease of use, they form the structure of the piggy bank.

- 3mm (1/8 inch) acrylic sheet: With a transparent front panel, you can see the contents of your bank clearly.

- Adhesive tapes and glue: It is used to secure the material to the CNC bed and ensure stability while cutting.

Bits used:

- 1/4 inch compression bit (top and bottom cut): Great for achieving clean edges on plywood.

- 1/8 inch O-flute bit: Selected for cutting acrylic without cracking or melting.

- 90° Diamond Drag Bit: Perfect for adding personalized engraving to acrylic surfaces.

Project Setup

Windsor Woodcraft makes wood and acrylic pieces. Genko PROVerXL 4030 V2 CNC MachineThe plywood was carefully cut with a 1/4″ compression bit to minimize tearing and achieve smooth edges. For the acrylic, a 1/8″ O-flute bit was used to achieve a precise cut without damaging the material. A 90° diamond drag bit was then used to engrave the acrylic, adding a customized touch to the design.

To secure the material to the CNC bed, he used a method that involves glue and tape, a reliable technique that ensures the material stays in place while cutting and can be easily removed without damage after cutting.

Assembly and Finishing

After cutting the pieces, assembling the piggy bank was easy. We considered two finishing options: painting the wood in SainSmart’s Signature Blue or staining it to show off the natural grain. To make the best choice, we tested both finishes on scraps of birch plywood, ultimately choosing the option that offered the most appealing contrast and finish.

He then drills small holes in the acrylic to attach it to the wood. He chose to do the work by hand rather than with a CNC machine for better control and precision. For those looking to add a little extra polish to their project, he recommends filling in any visible wood grain with wood putty or drywall putty before painting for a smoother finish.

As a final step, he Genko L8 20W Laser Engraving Machine We engraved our logo onto the back of the piggy bank, which added a unique and professional touch to the project and demonstrated the precision and detail that can be achieved with a laser engraving machine. The engraving process was easy and the result was a crisp, clean logo that enhanced the overall look of the piggy bank.

Final thoughts and variations

The finished piggy bank boasts clean cuts and a polished look, reflecting the high quality of the tools and craftsmanship. Masked, spray-painted lettering was also considered but ultimately omitted. The design is flexible; modifications such as using MDF or pine wood or adding a hole in the back for easier access allow the project to be adapted to different needs. This piggy bank is a functional and attractive piece, perfect for practicing CNC and laser engraving skills.