Over the last few years, there has been an explosion of open gantry diode-based laser cutters. Manufacturers have taken advantage of the availability of UV lasers from the Blu-ray player market, and these lasers have opened up the world of laser cutting to users who could not justify the expense of traditional CO2-based lasers. Solid-state devices are also much cheaper to manufacture because they do not require as much supporting hardware. However, the other side of the coin – safety – has been very costly. Reflections from open gantry UV lasers can blind a person before their blink response kicks in. This is not just a close-range issue, anyone within a few hundred feet is affected. Weekly Eight’s Vision We are up to the challenge of solving this problem.

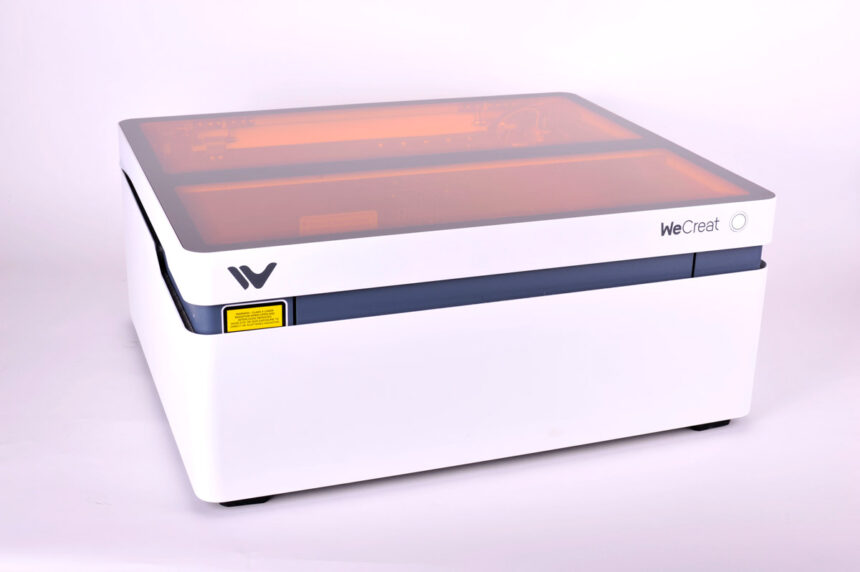

WeCreat Vision has achieved the perfect balance between convenience, safety, and functionality with a simple trick: a fully enclosed laser that automatically adjusts its height. The housing has double-walled sides, with an inner wall attached to the lid. A set of motors moves the lid up and down, allowing the machine to automatically focus on materials of various thicknesses, or to place optional rotating attachments inside the machine. The lid appears to be made of laser-blocking acrylic (although we can’t independently verify its effectiveness). The walls are metal, sealing out all dangerous laser radiation.

The lid rises 140mm and has a built-in HD camera. The camera makes cutting and material alignment easy and accurate. When the machine is fully extended, the rotary is easily positioned at the laser and there is a port to plug the rotary into without having to remove the Y-axis like many other lasers. If you don’t want a rotary and would like to engrave large sheet products instead, you can remove the bottom of the Vision and connect the optional (untested) extension and it will automatically feed in 145″ of material.

Of course, one of the other common problems with low-cost laser cutters is the software. You either get stuck with terrible, barely usable software, or pay extra for overly complicated options that are more focused on industrial production work than the needs of the average hobbyist or small shop. WeCreat has solved this problem as well with their excellent software called WeCreat MakeIt! (yes, there is an exclamation point in the name, I like it, but I’m not excited about it enough to have an exclamation point). Most of the features are fully available to the user, but you have to pay a subscription to access features such as the built-in AI image creation. The software has great features and can connect to the Vision via USB or Wi-Fi. Since I prefer to do my design creation in a CAD or vector drawing application, the basic drawing tools in MakeIt! are sufficient, and the simplicity makes for a clean interface. I really like that when choosing the power settings for a known material, you can choose from sample images of engraving density so you can judge how dense the engraving will be, rather than guessing the numbers and seeing the results.

Engraving and cutting worked well, although cutting was quite slow, as is common with the 20W diode (I’d like to see how the optional 40W head performs). I used the optional exhaust, which helped, but I would recommend venting it outdoors rather than relying on the exhaust filter. The autofocus feature worked well no matter how thick the material I put through the machine, and it was nice not to have to keep track of things like the focuser.

If you’re looking for a diode-based laser and plan on using it a lot rotary, especially for engraving mugs and tumblers, the WeCreat Vision is a great option and my top recommendation on the market right now.